Challenge

Today, operators lack the real-time tools to schedule their water hauls at the optimal time, and then have limited visibility to ensure that the pickups happen exactly as scheduled. The lack of an automated solution makes it difficult to maximize the number of barrels per haul and results in more short loads, costing operator’s money. One E&P company expressed these concerns and set off to find a solution.

Solution

Engage Mobilize’s order to cash solution was identified as a platform that provided the functionality to address their challenges. Information such as locations, cost centers and production data were passed into the Engage Mobilize system, so jobs could be predictively scheduled with the correct information in near to real-time. Water hauls are now scheduled at optimal times to maximize the volume of barrels pulled from a tank. Both the operator’s operational control center and the hauler’s dispatch managers can view their scheduled orders, current jobs and pending tickets, allowing for better planning and management.

Results

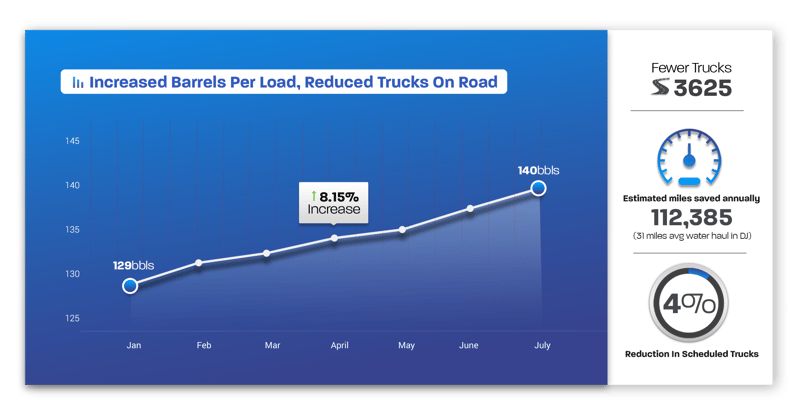

This study analyzed the first seven months that this operator was on the Engage Mobilize platform. Using data from over 45,000 tickets and 6.1 mil barrels transported, results showed a positive increase each month. The increase in barrels per load means that fewer trucks are needed to haul the same amount of water.

- The average barrels per load increased 8% from 129 bbls to 140 bbls in just 7 months

- Estimated 3,625 fewer trucks dispatched annually resulting in 112,385 fewer miles driven

Average Barrels per Load Increased 8% with Engage Mobilize for Water Hauls

Today, operators lack the real-time tools to schedule their liquid hauls at the optimal time, and then have limited transparency to ensure that the pickups happen exactly as scheduled. The lack of an automated solution makes it difficult to maximize the number of barrels per haul and results in more short loads, costing operator’s money. One E&P company expressed these concerns and set off to find a solution.

Solution

Engage Mobilize’s order to cash solution was identified as a platform that provided the functionality to address their challenges. The operator pushes their SCADA data and other production information into Engage Mobilize’s predictive algorithms, and based on predetermined parameters set by the operator, jobs are automatically scheduled for pick up and sent to their haulers in real-time. Both the operator’s operational control center and the hauler’s dispatch managers can view their scheduled orders, current jobs and pending tickets, allowing for optimal planning and management.

Results

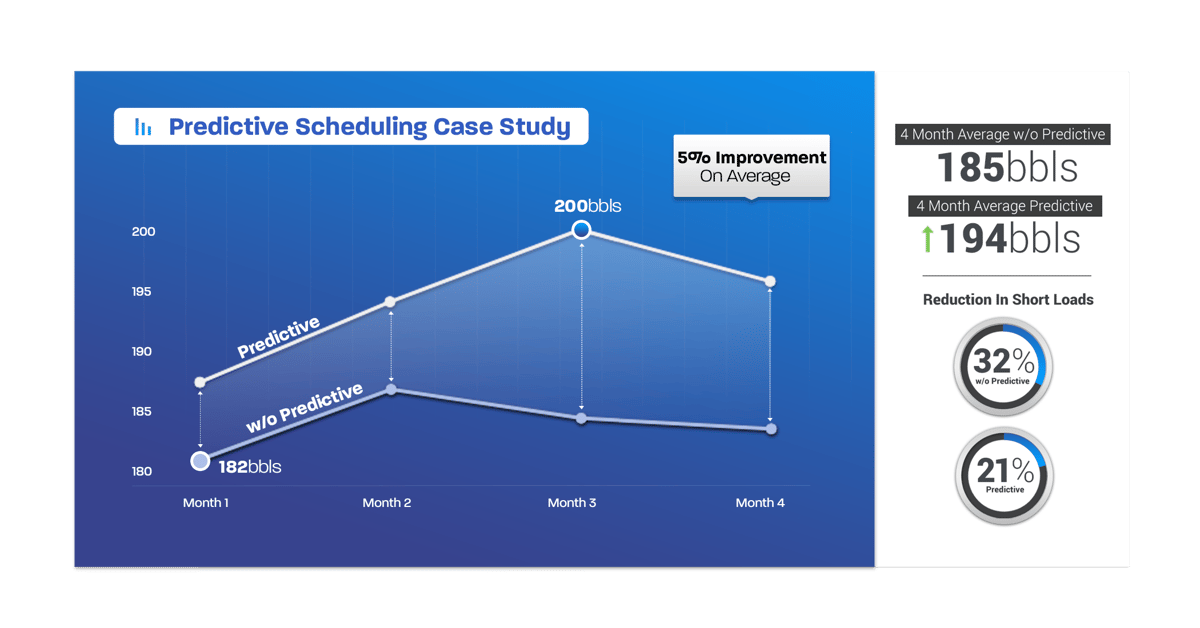

This study analyzed the last four months of crude hauls prior to Engage Mobilize and then measured the difference after implementing Engage Mobilize’s predictive scheduling and automated dispatch solution over the next four months. Using data from over 8,000 tickets, the average barrels per load increased from 184 bbls to 194 bbls using Engage Mobilize.

Using Engage Mobilize’s Predictive Scheduling, the average barrels per load increased from 184 bbls to 194 bbls for Crude Hauls

Challenge

An E&P Company was looking for a way to maximize productivity for some of their production services. Their challenge was not having any visibility into their service contractor activity, thus not being able to accurately track travel and work times on location.

Solution

The E&P company adopted the Engage Mobilize platform, providing real-time data for drive times, work times, and non-productive times. The Operator was able to strategically schedule crews/jobs based on location and availability. In addition, to the scheduling and real time re-routing capability, the Operator saw behavioral changes in their service contractor’s activity that increased their overall productivity.

Results

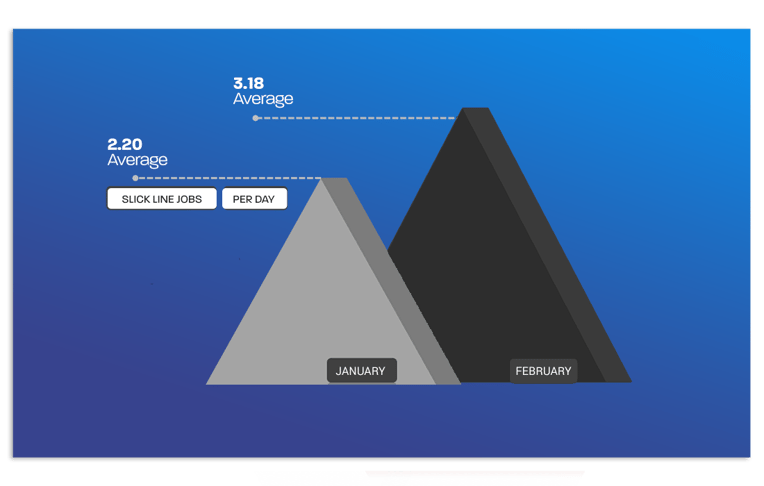

Data was analyzed from a post Engage Mobilize adoption timeframe and compared to a pre-adoption timeline. The data showed that the service company crews were doing on average 3.18 slick line jobs per day, compared to just 2.20 before implementation. This increase in wells serviced per day directly increased the quarterly production while lowering the operator’s cost per job by 9.6%.

Production enhancement jobs went from 2.2 jobs per day to 3.18 within the first 2 months with Engage Mobilize

Download Full Case Study

Complete this form to view ‘Increase Productivity’ Case Study.

Share this

Similar Stories

Simplify ESG Reporting by Automatically Capturing Scope 3 Emissions Data

Save Time